Telemetry Applications: Uses and Benefits Explained

Published: 4 Dec 2025

Telemetry applications have changed how modern industries operate by enabling precise monitoring, data collection, and analysis. Today, factories, energy grids, healthcare, and transportation all depend on industrial telemetry systems to boost efficiency, safety, and decision-making. These systems send real-time sensor and device data to central control centers for accurate monitoring.

Cloud-based telemetry lets managers monitor operations from anywhere, while endpoint telemetry tracks each device. When companies in the USA combine telemetry with analytics and automated reporting, they can prevent failures, use resources more effectively, and boost productivity. Wireless connections and strong system integration help keep everything running smoothly.

What Are Telemetry Applications and How Do They Work in Modern Industry?

Telemetry applications collect data from machines, vehicles, or sensors and send it to a central system. This process ensures that measurements such as temperature, speed, and pressure are delivered accurately. In today’s industries, this means production lines, energy grids, and transportation systems can be monitored in real time. Agent-based telemetry often sends device data to servers quickly. These systems use structured data transfer to keep information organized and easy to use in different applications.

Data from devices is collected and processed using network and telemetry protocols. Centralized monitoring helps companies spot problems early, plan maintenance, and run operations more efficiently. By using IoT data and remotely monitoring devices, industries can manage equipment from a distance. For example, a factory in Texas might use telemetry to monitor motor health, while a logistics company in California might track how its fleet is performing. These methods help save money, cut downtime, and boost productivity.

How Does Telemetry Improve Industrial Automation and Predictive Maintenance?

Today’s factories use industrial telemetry systems to automate tasks and avoid sudden breakdowns. By continuously monitoring equipment, teams can respond quickly and keep operations running efficiently. Real-time data helps make production more reliable and lowers costs.

- Telemetry data logging collects machine performance continuously for analysis.

- Telemetry event logging records unusual activities to help schedule preventive maintenance.

- High-frequency telemetry updates enable systems to adjust operations and reduce downtime dynamically.

- Endpoint telemetry monitors individual devices to ensure automation runs smoothly.

- Secure telemetry communication protects sensitive performance data from unauthorized access.

Predictive maintenance relies on real-time data from sensors on motors, pumps, and conveyors. By looking at telemetry performance data, engineers can predict problems and fix them before they cause trouble. Automotive plants in Detroit are good examples of how these methods help keep production running smoothly and efficiently.

How Is Telemetry Used in Energy, Utilities, and Smart Grid Monitoring?

Energy and utility companies use telemetry to safely manage their complex systems. Accurate monitoring helps them run efficiently and avoid outages. Real-time data provides operators with the information they need to make informed decisions across the grid.

Telemetry Data Pipelines

Telemetry data pipelines collect readings from transformers, smart meters, and substations and deliver them to centralized dashboards for analysis.

Wireless Telemetry Communication

Wireless telemetry communication is essential for remote sites, allowing continuous monitoring without physical connections.

Structured Telemetry Data Transfer

Structured telemetry data transfer ensures accurate, reliable readings that support operational decisions and compliance requirements.

Telemetry Performance Metrics

Operators use telemetry performance metrics to promptly detect energy loss, equipment failures, and overload risks.

IoT Data Transmission and System Integration

IoT data transmission and telemetry system integration connect grid data to cloud analytics, enabling smart grids to adjust supply dynamically and support renewable energy efficiently.

Telemetry Network Protocols

Telemetry network protocols and network telemetry maintain secure, stable communication across the entire energy infrastructure.

What Role Does Telemetry Play in Transportation, Fleet Management, and Logistics?

Fleet managers use telemetry to track vehicles, fuel consumption, and driver performance. Real-time data helps companies work more efficiently and lower their costs. Accurate information also makes operations safer and supports better decisions.

- Telemetry data monitoring provides instant updates on fleet performance and vehicle conditions.

- Endpoint telemetry captures detailed data from each vehicle for centralized analysis.

- Agent-based telemetry transfer ensures that updates reach central systems promptly.

- Telemetry performance metrics help schedule maintenance and optimize routes efficiently.

- Telemetry event logging records delays or incidents to improve safety. When you connect IoT data and telemetry with cloud platforms, your logistics team can cut fuel costs and speed up deliveries. Telemetry keeps your operations running smoothly and makes fleet management safer and easier. Ment overall.

How Does Telemetry Support Healthcare and Remote Patient Monitoring?

Patient vitals, medications, and equipment in real time.

With cloud-based systems, doctors can monitor patients from anywhere, and secure connections keep data private. Fast updates mean you get instant alerts if a patient’s condition changes. Hospitals across the USA rely on these tools for ICU care, telemedicine, and home monitoring.

Telemetry data logging and telemetry event logging record trends for analysis. IoT data transmission from wearable devices helps track heart rate, blood pressure, and glucose levels. Structured telemetry data transfer enables integration with electronic health records, allowing clinicians to make informed decisions quickly. This technology reduces hospital readmissions and improves patient outcomes.

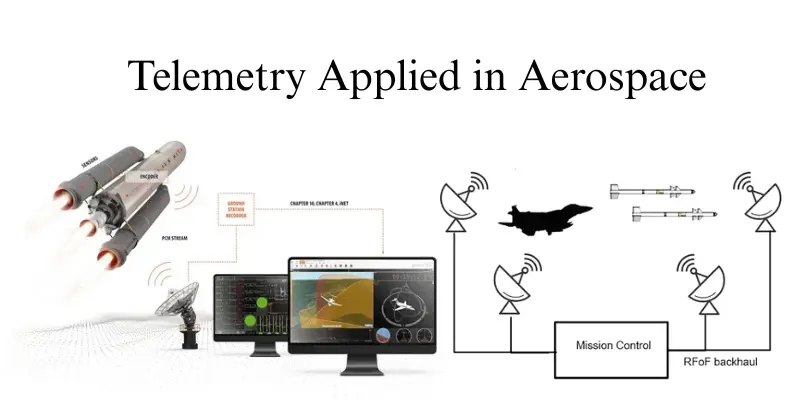

How Is Telemetry Applied in Aerospace, Defense, and Space Systems?

Telemetry is essential for aerospace, defense, and space missions. Satellites, drones, and spacecraft constantly send crucial data. Careful monitoring helps ensure missions succeed and remain safe.

Telemetry Signal Transfer

Reliably transferring telemetry signals delivers mission-critical information from vehicles to command centers in real time.

High-Frequency Telemetry Updates

High-frequency telemetry updates enable engineers to monitor altitude, speed, and system health in real time, supporting rapid decision-making.

Network Telemetry and Agent-Based Transfer

Network telemetry connects remote systems to ground stations, while agent-based telemetry continuously keeps command centers updated with flight data.

Telemetry System Integration

Telemetry system integration combines multiple data streams, ensuring seamless monitoring and accurate post-mission analysis.

Structured Telemetry Data Transfer and security

Structured telemetry data transfer keeps data organized, and secure telemetry communication protects sensitive information during transmission.

Remote monitoring of natural and industrial sites is critical for safety and efficiency. Telemetry provides real-time insights from rivers, forests, and industrial areas. Accurate data helps teams respond quickly to risks and operational issues.

Wireless Telemetry Communication

Wireless telemetry enables sensors to transmit data from remote, hard-to-reach locations, ensuring continuous monitoring without physical connections.

Telemetry Data Pipelines

Telemetry data pipelines efficiently deliver sensor readings to central systems, enabling analysis and rapid decision-making.

Endpoint Device Monitoring Transmission

Endpoint device monitoring transmission tracks the health and status of equipment in real time, reducing downtime and improving safety.

Telemetry Performance Metrics

Teams use telemetry performance metrics to promptly detect leaks, pollution, and unsafe conditions, ensuring compliance and operational reliability.

Secure Telemetry Communication and Cloud Integration

Secure telemetry communication protects sensitive data, while IoT data transmission and cloud-based telemetry allow operators to make informed decisions from remote locations efficiently.

What Impact Do IoT and Cloud Platforms Have on Industrial Telemetry?

Cloud integration enables real-time data transfer from multiple endpoints. Cloud-based telemetry platforms store vast amounts of information for analytics. Telemetry system integration with cloud dashboards enables managers to track telemetry performance metrics across facilities instantly. These systems reduce downtime and improve productivity.

IoT devices expand telemetry coverage by providing endpoint- and agent-based data collection. Telemetry data from thousands of devices is fed into a structured telemetry data transfer system, helping engineers identify patterns and optimize operations. USA industries like manufacturing, logistics, and healthcare benefit from centralized, cloud-driven telemetry systems.

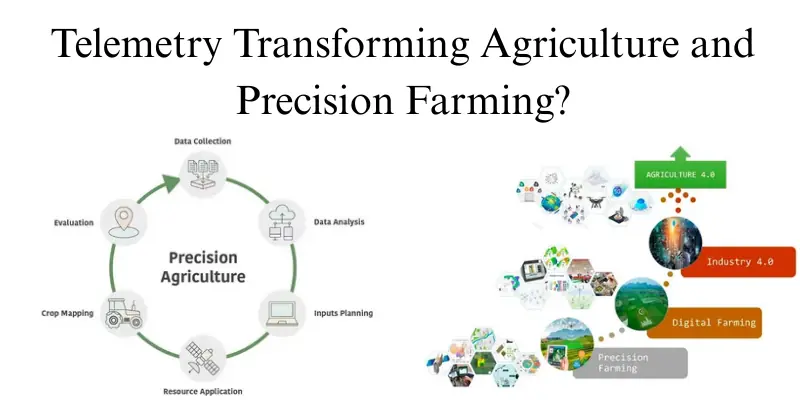

How Is Telemetry Transforming Agriculture and Precision Farming?

Precision agriculture is transforming how farmers manage their fields. Telemetry enables detailed monitoring of soil, water, and crop conditions. Real-time data helps optimize farming decisions and reduce waste.

IoT Data Transmission

Sensors in the field continuously send data on moisture, temperature, and nutrient levels. IoT data transmission ensures this information reaches farm management systems instantly.

Endpoint Device Monitoring Transmission

Tractors, drones, and irrigation systems are tracked for efficiency. Endpoint device monitoring transmission ensures equipment works correctly and resources are used wisely.

Telemetry Performance Metrics

Farmers analyze telemetry performance metrics to optimize yields. Metrics such as water use, crop growth, and soil health inform decision-making.

Cloud-Based Telemetry and Data Pipelines

Data flows through telemetry data pipelines into cloud-based telemetry dashboards. This integration with industrial telemetry systems helps farms improve productivity while minimizing environmental impact.

What Are the Main Challenges and Best Practices in Industrial Telemetry?

Industrial telemetry is essential to modern industries, but it also poses several challenges. Companies face massive data volumes, security risks, and potential network reliability issues. Handling all this information efficiently requires careful planning and robust systems.

- Secure telemetry communication and telemetry network protocols protect data from cyber threats and unauthorized access.

- Telemetry data logging and telemetry event logging ensure historical records are maintained for compliance and future analysis.

- Structured telemetry data transfer and agent-based telemetry transfer streamline data flow across multiple endpoints and systems.

- Telemetry system integration and monitoring telemetry performance metrics help maintain smooth operations and system reliability.

Following these best practices, along with regular audits, cloud redundancy, and high-frequency telemetry updates, improves overall efficiency. Industries in the USA can operate more safely, minimize downtime, and maximize productivity using these proven strategies.

Frequently Asked Questions about Telemetry Applications

Telemetry applications help industries track performance, monitor devices, and make wise decisions. Here are common questions people ask about these systems and how they work in modern industries.

They are used to monitor equipment, track performance, and collect real-time data to support better decision-making.

By providing real-time insights, it helps prevent failures and optimize processes.

Yes, it remotely monitors patient health and efficiently tracks medical devices.

It tracks vehicles, fuel usage, and driver behavior to improve safety and reduce costs.

Secure telemetry communication and encryption protect information from unauthorized access.

Manufacturing, energy, transportation, agriculture, healthcare, and defense gain the most advantages.

They enable cloud-based telemetry, real-time data collection, and seamless system integration.

Conclusion

Telemetry applications have become the backbone of modern industries in the USA. By enabling real-time data transfer, industrial telemetry systems, and cloud-based telemetry, companies can monitor operations, prevent failures, and optimize resources effectively. These systems connect devices, sensors, and machines through endpoint telemetry and integrated telemetry data pipelines, providing continuous insights into performance and safety.

As industries adopt IoT and wireless technologies, telemetry applications expand further, supporting more intelligent factories, efficient energy grids, safer transportation, and advanced healthcare monitoring. Implementing secure telemetry communication, structured data transfer, and high-frequency updates ensures reliable and accurate results. Investing in telemetry today empowers businesses to operate efficiently, reduce risks, and make informed decisions for the future.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks